WHY REWIND?

Why Rewind?

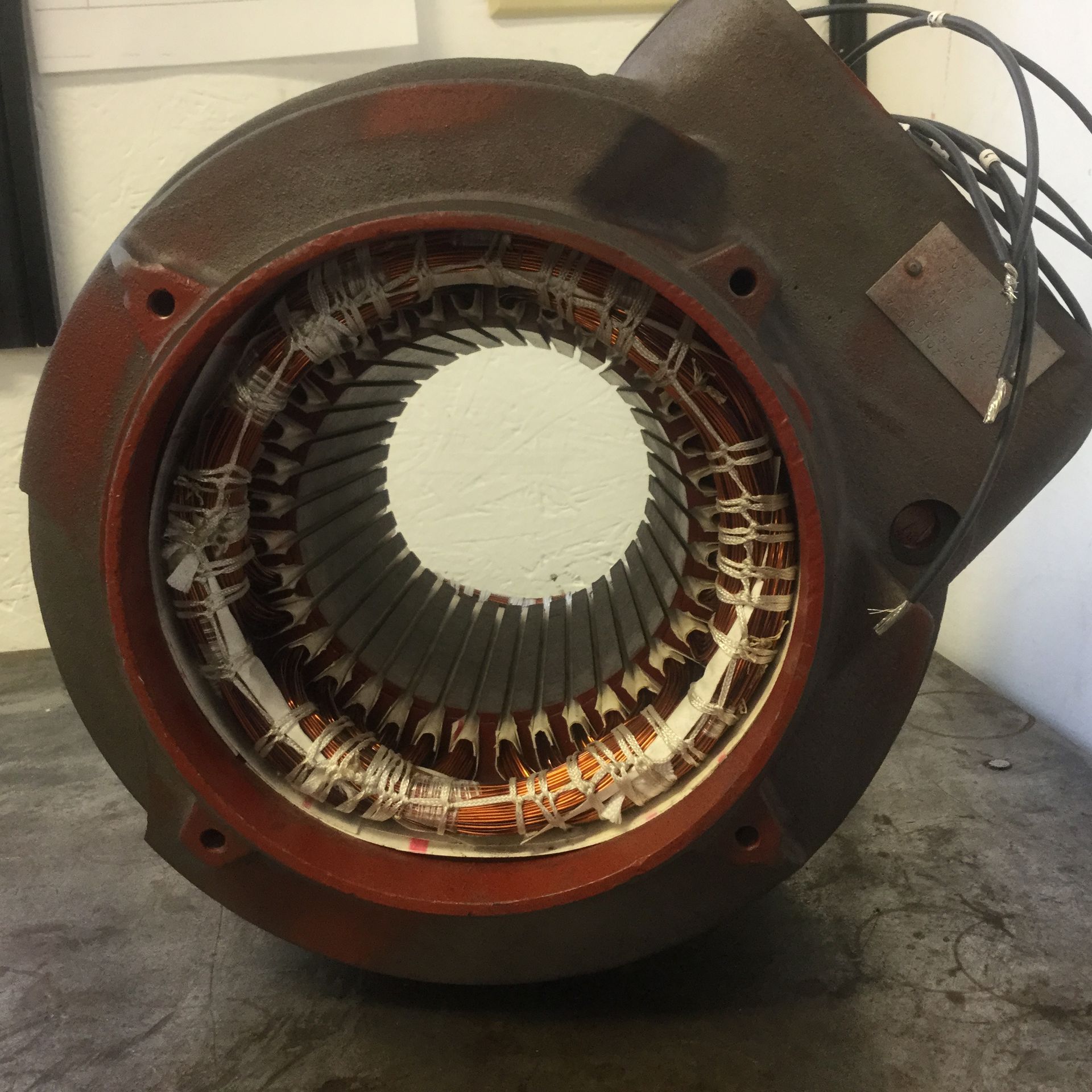

ELECTRIC MOTOR REWINDINGfor the Erie, PA Area

WHY REWIND? Below are some of the advantages of electric motor rewinding or coil rewinding versus replacing your motor!

COST

There is usually significant cost savings in rewinding a larger horsepower motor than replacing with new. This is especially the case when a replacement motor is unique to a piece of equipment (not a stock motor) and has to be purchased through the OEM provider. (We can usually provide a comparison quote between new and rewind options.)LEAD TIME

Ordering a new replacement motor from an OEM provider can involve up to several weeks lead time from the manufacturer (especially the case with motors manufactured in Europe). When our customer is in need of a rush repair, we do our best to provide a quick turnaround and get our customer's operations back up and running as soon as possible.

ORIGINAL MOTOR IS OBSOLETE

(replacement not available) - Rewinding an original older motor makes it possible to continue using your older equipment without any modifications.

CUSTOM REWIND / REDESIGN FOR CUSTOMER'S SPECIFIC NEEDS:

• Change voltage (For instance, a motor which is currently 575 volt can be rewound to 230 volt or whatever voltage is needed)

• Change voltage for increased efficiency (motors can be rewound to specific line voltage coming into the customer's facility, thus increasing equipment efficiency)

• Change horsepower (can rewind to boost horsepower to a limited extent)

• Change RPM

• Increase insulation temperature

Contact Us

Today to Learn More About Electric Motor Rewinding!

Follow Us

Lyons Electric Motor Service Inc

1427 East 10th St.

Erie, PA 16503

ph 814-419-9485

WEB DESIGN

BY LOCALEDGE,

ALL RIGHTS RESERVED

Call for electric motor repairs!

814-419-9485